QHSE department is involved in Quality Management, Quality Assurance, Quality Control and Health, Safety & Environmental aspects of all company’s projects.

This includes all activities of the planning & documentation and also operational & inspection activities (at the project sites). QHSE department is an independent division and directly works under supervision of the Managing Director of SADAF.

At SADAF, an IMS (Integrated Management System) based on the ISO 9001:2004, ISO 14001:2004 and ISO 18001:1999 requirements is founded and the quality is achieved and maintained by working in a systematic manner to formalized procedures.

The management data system of a company, even in its highest level insists on doing the quality management activities.

This quality management system is an un concentrated responsibility that means, all the employees are responsible to recognize the specific needs and take an action for changing un credible needs. Our primary objective is to satisfy clients by achieving a high level of effectiveness and efficiency in each phase of project (Engineering, procurement, manufacturing and installation), and to meet the clients’ expectations, stated and implied.

In this regard, compliance with Quality, Health, Safety and Environment is as a minimum requirement in SADAF.

Throughout innovation and contemporary technology in execution of EPCI projects, development and promotion in IMS efficiency is continually implemented, and with process management, SADAF is able to achieve targets & objectives.

Quality Management Principles:

-

Customer Focus:

Organizations depend on their customers and therefore should understand current and future customer needs, should meet customer requirements and strive to exceed customer expectations.

-

Leadership:

Leaders establish unity of purpose and direction of the organization. They should create and maintain the internal environment in which people can become fully involved in achieving the organization’s objectives.

-

Involvement of People:

People at all levels are the essence of an organization and their full involvement enables their abilities to be used for the organization’s benefit.

-

Process Approach:

A desired result is achieved more efficiently when activities and related resources are managed as a process.

-

System Approach to Management:

Identifying, understanding and managing interrelated processes as a system, contributes to the organization’s effectiveness and efficiency in achieving its objectives.

- Continual Improvement:

Continual improvement of the organization’s overall performance should be a permanent objective of the organization.

-

Factual Approach to Decision Making:

Effective decisions are based on the analysis of data and information.

-

Mutually Beneficial Supplier Relationship:

An organization and its suppliers are interdependent and a mutually beneficial relationship enhances the ability of both to create value.

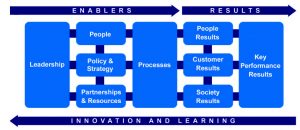

In Line with Integrated Management System, SADAF excellence will be implemented according to FEQM model, and Project Management is complied with PMBOK requirements to achieve high level of clients’ satisfaction and also project operation.

Exceeding minimum legal requirements is known as one of the objectives in SADAF and developing partnership to establish added values is a core priority.

SADAF is committed to achieve the highest Standards of Health, Safety and Environment within all its activities.

The first stage of HSE Management system is “identification of risks and environmental impacts” and will be continually revised and developed.

Facts of HSE management:

SADAF HSE (Health, Safety and Environmental) Management is developed in all projects, plants and fleets. HSE performances are periodically audited and results reviewed by Top Management and appropriate decisions are taken.

We believe in,

- All incidents are preventable.

- Health, Safety and Environmental issues have priority to all activities.

- Compliance with relevant national and international legislations and standards is a minimum requirement in HSE management.

- Health, safety and environment protection is the responsibility of all SADAF personnel.

Subcontractors and suppliers performances are considered in SADAF HSE management and one of the appraisal criterion is the compliance with HSE requirements. Their activities are audited and evaluated in order to ensure that healthy and safe conditions are maintained at the working sites and also on damages to environment.

ISO Certificates: